The Machining Manufacturing Process

The machining manufacturing process is a fundamental part of modern industrial production. It involves removing material from a raw workpiece to obtain the required shape, dimensions, and surface finish. Machining is widely used in industries such as automotive, aerospace, machinery, energy, and equipment manufacturing. At Shanghai Weilei Trading Company, machining manufacturing is regarded as a core capability to ensure product quality and reliability.

The process typically begins with material selection and preparation. Common materials used in machining include carbon steel, alloy steel, aluminum alloys, stainless steel, and engineering plastics. The raw material is cut or pre-processed into suitable sizes to ensure efficient and accurate machining in subsequent steps.

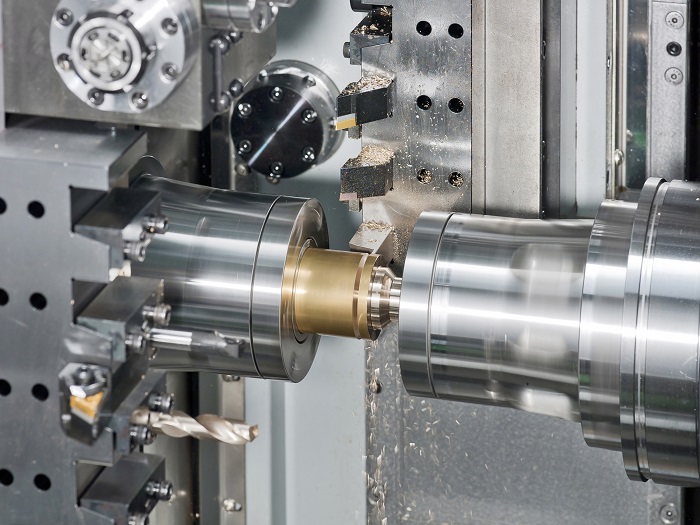

Next, machining operations are carried out using various machine tools. Common processes include turning, milling, drilling, boring, grinding, and tapping. These operations are performed based on engineering drawings and technical specifications. CNC (Computer Numerical Control) machines are widely used to achieve high precision, consistency, and repeatability, especially for complex and high-tolerance components.

Process planning plays a critical role in machining manufacturing. This includes selecting appropriate cutting tools, machining parameters, and machining sequences. Proper planning helps improve efficiency, reduce tool wear, and ensure dimensional accuracy. Coolants and lubricants are often used during machining to control temperature, improve surface finish, and extend tool life.

After machining, parts usually undergo finishing processes such as deburring, polishing, surface treatment, or heat treatment. These steps enhance surface quality, mechanical properties, and corrosion resistance, depending on application requirements. Shanghai Weilei Trading Company follows strict production standards and quality control procedures to ensure that every machined component meets customer and international requirements.

Quality inspection is an essential stage of the machining manufacturing process. Measuring tools such as calipers, micrometers, and coordinate measuring machines (CMM) are used to verify dimensions and tolerances. Strict inspection ensures that each part meets design requirements and quality standards.

In conclusion, the machining manufacturing process combines advanced equipment, professional expertise, and rigorous quality control to produce high-quality mechanical components. Continuous improvement in machining technology enables manufacturers to deliver reliable and precision-engineered products for global industries.