Machining and Precision Mechanical Manufacturing

Machining and precision mechanical manufacturing play a crucial role in modern industrial production. With the rapid development of advanced manufacturing technologies, the demand for high-precision, high-quality mechanical components has increased significantly in industries such as aerospace, automotive, medical devices, and electronics.

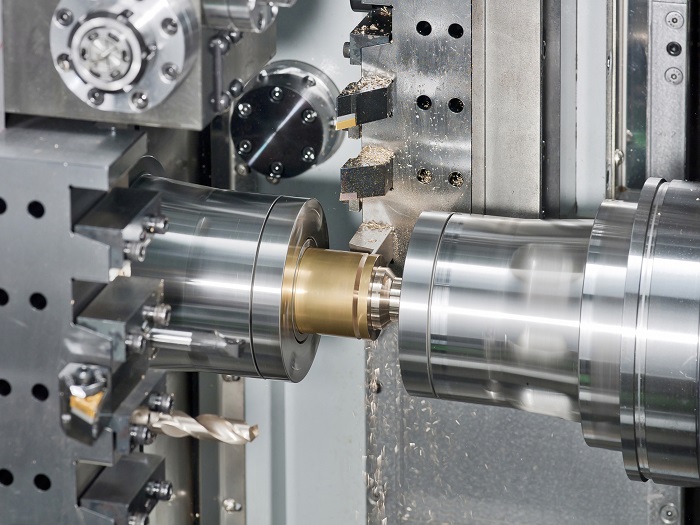

Machining refers to the process of removing material from a workpiece to achieve the desired shape, size, and surface finish. Common machining methods include turning, milling, drilling, grinding, and electrical discharge machining (EDM). These processes are typically carried out using machine tools such as lathes, milling machines, and machining centers. The accuracy and efficiency of machining directly affect the performance and reliability of mechanical products.

Precision mechanical manufacturing focuses on producing components with extremely tight tolerances and superior surface quality. In this field, dimensional accuracy is often measured in micrometers, and even minor deviations can lead to functional failure. To achieve such precision, advanced equipment such as CNC (Computer Numerical Control) machine tools is widely used. CNC machining enables high repeatability, automation, and complex geometry production, greatly improving manufacturing efficiency and consistency.

Material selection is another key factor in precision machining. Common materials include steel, aluminum alloys, titanium alloys, and engineering plastics. Each material has different mechanical properties and machining characteristics, requiring appropriate cutting tools, parameters, and cooling methods. Proper material processing helps reduce tool wear, improve surface quality, and ensure dimensional stability.

Quality control is essential in precision mechanical manufacturing. Measuring instruments such as coordinate measuring machines (CMM), laser scanners, and optical measuring systems are used to inspect dimensions and tolerances. Strict quality management systems ensure that every component meets design and performance requirements.

In conclusion, machining and precision mechanical manufacturing are fundamental to the advancement of modern industry. As technology continues to evolve, the integration of intelligent manufacturing, automation, and digital control will further enhance precision, efficiency, and reliability, driving the future development of mechanical engineering.